Maintenance and Longevity Tips for Patch Cord and Pigtail

Home » Maintenance and Longevity Tips for Patch Cord and Pigtail

RECENT POSTS

Share:

- September 15, 2025

Table of Contents

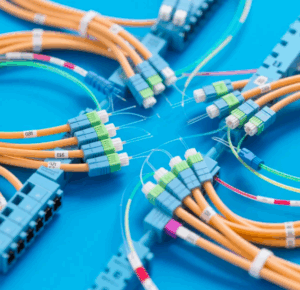

In any modern network, patch cord and pigtail are essential components that connect devices reliably and maintain smooth data flow. Proper maintenance can greatly extend their lifespan, reduce network downtime, and save costs. Neglecting basic care can lead to signal degradation, frequent replacements, or network disruptions. This article provides practical tips and innovative approaches to maintain patch cord and pigtail, ensuring optimal performance in different settings.

Patch Cord and Pigtail Handling Best Practices

(1)Safe Handling and Installation

Proper handling is the first step to prolonging the life of patch cord and pigtail.

- Avoid excessive bending: Maintain the bend radius above 30 mm for single-mode fibers and 20 mm for multi-mode fibers. Bending beyond these limits can increase insertion loss and create microcracks that worsen over time, eventually causing fiber failure.

- Do not pull excessively: Most patch cords can handle 50–100 N of tensile strength. Pulling beyond this can break the fiber core or damage connectors.

- Clean hands and tools: Dirt or grease can scratch connectors, causing signal loss. Use lint-free wipes or isopropyl alcohol for cleaning before installation.

(2)Connector Protection

Connectors are the most vulnerable part of patch cord and pigtail.

- Dust caps: Keep dust caps on unused connectors. Dust or lint can reduce signal quality, especially for high-speed links of 10 Gbps or above.

- Regular cleaning: Wipe connectors gently before use. Even small particles can degrade performance.

- Visual inspection: Check connectors under a small magnifier to ensure no scratches or dirt. Damaged connectors should be replaced immediately.

Environmental Factors Affecting Longevity

(1)Temperature and Humidity Control

Environmental conditions affect the lifespan of patch cord and pigtail.

- Temperature range: Indoor patch cords usually tolerate 0–70°C, while outdoor or armored types withstand −40°C to 85°C. Exposure beyond these limits can reduce fiber strength by 10–20% and cause slow performance decline over time.

- Humidity: Moisture can seep into jackets, especially for non-armored fibers. Keep humidity below 80% to prevent swelling or corrosion.

(2)Dust and Contaminants

Dust, smoke, or industrial particles accelerate wear.

- Example: In schools or small labs, cables should be organized in trays or conduits to minimize dust accumulation. Proper cleaning and cable routing prevent connection issues and maintain smooth signal transmission.

Innovative Maintenance Approaches

(1)Modular Cable Management

Using cable organizers reduces stress on patch cord and pigtail.

- Scenario: In a school lab, labeling cords and routing them with Velcro straps prevents accidental tugs and keeps bend radius above 30 mm. This simple method reduces connector damage and maintains stable performance.

(2)Rotational Usage and Redundancy

- Technique: Rotate patch cords in high-use areas, such as classrooms or temporary events, to distribute wear evenly.

- Benefit: Extends the lifespan of each cord by up to 20% compared with continuous single-use deployment, maintaining consistent network reliability.

(3)Protective Jackets and Armored Cables

- Application: In factories or outdoor setups, use armored jackets.

- Benefit: Armored patch cords resist abrasion and accidental impacts. Tensile strength increases to 200 N, and lifespan can extend by 2–3 years under harsh conditions.

Practical Tips for Daily Maintenance

- Label clearly: Use color-coded or numbered labels to track connections.

- Store properly: Coil unused cords loosely; avoid kinks or tight loops.

- Check regularly: Monthly visual inspections help spot bends, dirt, or minor damage. Ensure cords are not pinched or stressed in trays.

- Clean connectors: Wipe with a soft cloth or use fiber cleaning tools to remove dust.

- Replace proactively: If a connector shows wear or repeated issues, replace it early to prevent network interruptions.

Applications Practical Examples: Protection Methods for Single-, Duplex, and Multi-Core Fibers

- Classroom or Office Setup:In busy classrooms or small offices, cables are frequently moved or unplugged. Using Velcro straps to secure patch cord and pigtail along desks or cable trays prevents accidental tugs, sharp bends, and connector stress. Regular visual inspections and gentle cleaning of connectors ensure the network stays reliable while the cords last longer.

- Temporary Event or Workshop:During workshops or temporary events, patch cords are often set up and removed daily. Rolling cords loosely, avoiding tight loops, and storing them in protective cases reduces microbends and physical wear. Implementing a rotational usage system, where different cords are used each day, helps distribute wear evenly and extends overall lifespan.

- Factory or Lab Environment: In spaces with machinery or frequent foot traffic, protective sleeves or armored jackets on patch cord and pigtailprevent abrasion and accidental damage. Periodically checking for kinks, twisted connectors, or excessive tension ensures that cords maintain optimal performance and longevity, even in high-stress environments.

Conclusion

Maintaining patch cord and pigtail properly is crucial for network reliability and efficiency. From careful handling and environmental control to modular management, rotational usage, and proactive cleaning, these practices extend cable lifespan and reduce costs.

By applying these simple yet effective tips, network users—whether in homes, schools, or factories—can ensure stable connections, smooth data flow, and long-term performance without relying on complex testing equipment. Proper care of patch cord and pigtail is key to sustaining both hardware longevity and overall network quality.

0