Can a bottle filling and capping machine handle all bottle types?

Home » Can a bottle filling and capping machine handle all bottle types?

RECENT POSTS

Share:

- August 13, 2025

Table of Contents

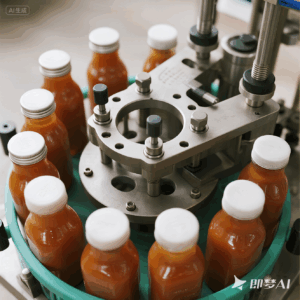

Today, companies often deal with a wide variety of bottle shapes, sizes, and materials, from glass and plastic to metal and even environmentally friendly biodegradable materials. This diversity raises an important question: Can a bottle filling and capping machine handle all bottle types?

The short answer is yes. Many modern machines can handle a wide range of bottle types, but there are some important details to understand before investing.

1. Compatibility of the Bottle Filling and Capping Machine with Different Bottle Materials

A key factor to consider is whether the bottle filling and capping machine is compatible with the materials you are using. Different materials react differently during the filling and capping process.

- Glass bottles are strong and heat-resistant, making them ideal for hot-fill products like sauces or beverages, but they can break if not handled smoothly. A machine must utilize a gentle gripping system and a stable conveyor belt.

- Plastic bottles are lightweight and versatile, but they can easily deform under high temperatures or pressure. A high-quality machine should be equipped with adjustable grippers and guides to prevent bottle breakage.

- Metal bottles offer exceptional durability, but require precise torque control during the capping process to prevent damage to the threads or seal.

- Biodegradable bottles or sustainable packaging materials may require more gentle handling to maintain their integrity.

A well-designed bottle filling and capping machine should be equipped with adjustable grippers, conveyors, and guides to fine-tune for all of these materials without causing defects or delays.

2. Bottle filling and capping machines flexibly adapt to different shapes and sizes.

- Not all bottles are round. Modern packaging uses square, oval, and uniquely contoured bottles to stand out on store shelves. Each shape presents unique handling challenges.

- Versatile bottle filling and capping machinesshould include features such as adjustable height and width guides to accommodate bottles of varying diameters and heights; interchangeable filling heads and capping chucks to accommodate a variety of capping styles; and quick component changeovers to minimize downtime when switching between products.

- For example, in a beverage plant, the same machine might be able to fill both small 250ml juice bottles and large 2-liter water bottles. Without flexible components, switching sizes would require lengthy adjustments or multiple machines. Well-equipped systems, however, can make adjustments in minutes, improving efficiency.

3. Bottle Filling and Capping Machine Compatibility with Bottle Cap Types

- The type of cap is just as important as the bottle itself. A bottle filling and capping machine must be able to handle screw caps, snap caps, sport caps, corks, and other types of closures.

- Some capping systems are designed for only one type of closure, while others can handle multiple types.

- For example, screw caps require precise torque settings to ensure a secure seal. Snap caps require downward force to securely close.

- Sports caps or flip-top caps may require additional calibration to function properly.

- If your production line includes multiple closure types, choose a machine with a modular capping head or one that can be upgraded to accommodate new designs in the future.

4. Limitations of Bottle Filling and Capping Machines

Even with advanced technology, bottle filling and capping machines may have some limitations:

- Extremely small or oversized bottles may require separate handling equipment. Irregular bottle shapes may require custom clamps or guides.

- Products with unusual textures or thicknesses may require specialized filling pumps. Caps with complex sealing mechanisms may require custom tooling.

The best way to avoid problems is to test the machine with actual bottles and caps before purchasing. This ensures smooth operation and avoids production issues.

5. Choose the Bottle Filling and Capping Machine That Suits Your Needs

- To ensure your bottle filling and capping machinecan handle all bottle types, look for models with high adjustability, modular components, and room for upgrades.

- Key features include: a wide bottle size range, adjustable torque and pressure settings, compatibility with different caps, multiple filling methods, and quick, tool-free product changeovers.

- If you plan to expand your product range in the future, choosing a flexible, scalable machine now will save you time and money.

Conclusion:

Modern bottle filling and capping machines can handle most types of bottles, especially if there is flexibility in the design.

High-quality models can accommodate different materials, shapes, sizes, and cap types while minimizing downtime.

0